I'll assume you're watching this video because you're either ing some periodic maintenance to your Bennett trim tabs or you're doing some troubleshooting with a minor problem that you've had. One thing that's helpful to understand is that this is an electro-hydraulic system. What that means is each trim tab system has a control which allows you to independently move the tabs, and it sends electric signals to an electro hydraulic power unit. This power unit consists of two independent solenoid valves and a reversible motor. You run the motor in forward to put the trim tabs down, and you run the motor in reverse to bring them back up. This moves fluid into a slave cylinder, which pushes the trim tab down, allowing water flow to be deflected, the stern to raise, and the bow to be lowered. Oftentimes, when we're helping with troubleshooting at Bennett, we run into the problem where one trim tab works perfectly, yet one trim tab isn't moving at all. The boat owner is often led to believe that the problem was with the hydraulic cylinder, when in fact we should be looking somewhere else to diagnose this problem. What's most important to understand is that the two solenoid valves on top of the power unit individually control the two trim tabs. You've got one valve for the starboard side and one valve for the port side. They're color-coded green and red as appropriate. When we have one tab that does not want to move, it means one of these valves is either not getting power or it is burned out because it's had power on it too long. It's also important to keep in mind that just because you hear the motor running doesn't mean that the valve itself is working. With the ground wire for...

Award-winning PDF software

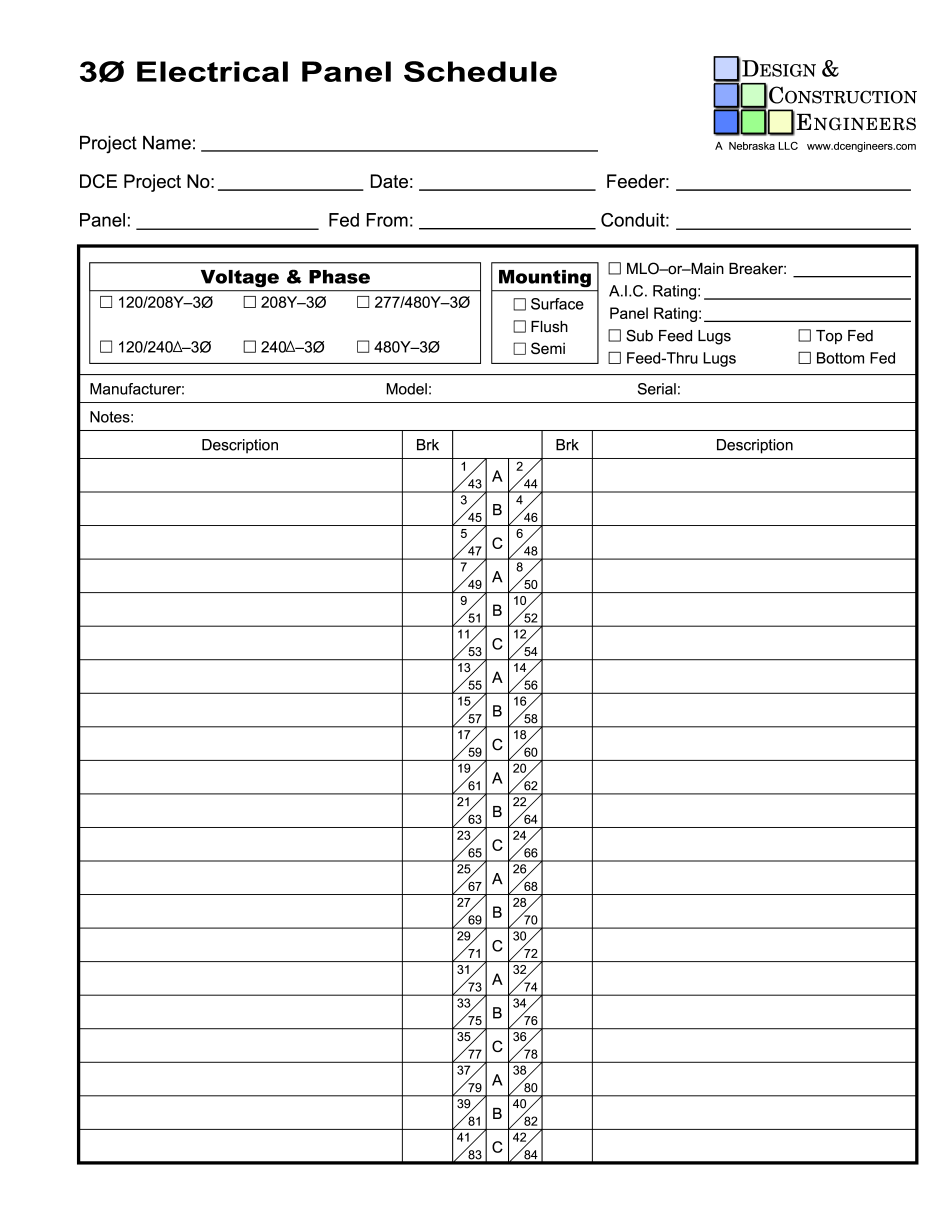

Electrical dwg Form: What You Should Know

Electrical — CAD, DWG, Drawings, PDF Free 3D Electrical drawings and blocks in DWG, for use with AutoCAD and other 2D and 3D design software. Electrical — CAD, DWG, Drawings, PDF Free 3D Electrical CAD drawings and blocks in DWG, for use with AutoCAD and other 2D and 3D design software. Electrician's drawings in DWG format, for use with AutoCAD Architectural Electrical and Electrical Design. Tutorial 2 A quick tutorial for the beginner in converting DWG drawings of the ACID/ASHE specifications into CAD files. Tutorial: How to convert DWG/PDF drawings into CAD Tutorial 3 A very simple and beginner's tutorial for the conversion of DWG files from the AOS/AIS/DMS/DRC to AutoCAD. Tutorial — How to convert DWG/PDF files into AutoCAD drawings Tutorial: Using an Inventor to convert DWG files from DWG to CAD and PDF files. Electrical symbols DWG/Graphic Symbols — Free CAD Blocks in DWG to download for use with your AEC / ATB / AIS / DRC or other 2D or 3D CAD software. The DWG symbol drawings have been developed by Ira, using a combination of Adobe Illustrator and AutoCAD. Inventor symbols DWG/Graphic Symbols — Free CAD Blocks in DWG to download for use with your AEC / ATB / AIS / DRC or other 2D or 3D CAD software. The DWG and Graphic Symbols have been developed by Ira and are available freely on this site in two formats. CAD graphic symbols DWG/Graphic Symbols — Download CAD symbols in DWG to PDF format for use with your DCC software or for publishing in a 3D design software. A very useful and good-looking PDF file format that allows the users to share the 3D drawings and graphic symbols with a large audience in a very easy manner. CAD symbol DWG/A Symbol — DWG symbols in DWG format for use with your DCC software or for use with a 3D design software where you need many DWG/A symbol files.

online solutions help you to manage your record administration along with raise the efficiency of the workflows. Stick to the fast guide to do Electrical Panel Schedule, steer clear of blunders along with furnish it in a timely manner:

How to complete any Electrical Panel Schedule online: - On the site with all the document, click on Begin immediately along with complete for the editor.

- Use your indications to submit established track record areas.

- Add your own info and speak to data.

- Make sure that you enter correct details and numbers throughout suitable areas.

- Very carefully confirm the content of the form as well as grammar along with punctuational.

- Navigate to Support area when you have questions or perhaps handle our assistance team.

- Place an electronic digital unique in your Electrical Panel Schedule by using Sign Device.

- After the form is fully gone, media Completed.

- Deliver the particular prepared document by way of electronic mail or facsimile, art print it out or perhaps reduce the gadget.

PDF editor permits you to help make changes to your Electrical Panel Schedule from the internet connected gadget, personalize it based on your requirements, indicator this in electronic format and also disperse differently.

Video instructions and help with filling out and completing Electrical dwg